An approach to reducing energy & Water consumption

Building systems can be complex

Understanding them doesn't have to be

Why are buildings cool? Because we spend 90% of our lives inside buildings.

What is your objective?

Building Basics

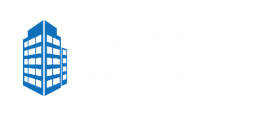

Why do we need buildings anyways? Well, they allow us to congregate in a comfortable place when it is hot or cold outside. In fact, we spend 90% of our lives inside buildings! Buildings also provide a space to conduct science, build technology, and provide entertainment. Buildings consume quite a bit of energy in most common forms of electricity, natural gas, and water in order to keep us safe, comfortable, and to produce products.

The industry is very good at providing fresh air, comfort, and keeping processes going, however, when diligence is not used there is a lot of energy waste.

Energy Flow

Building Perspective

Why Should we care?

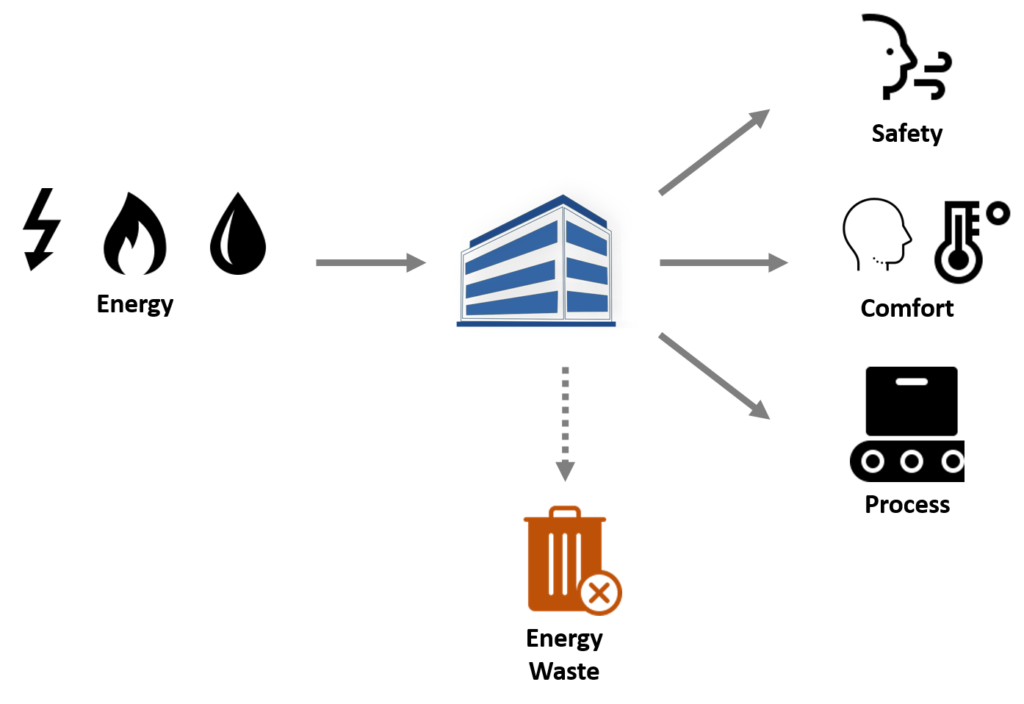

Sustainability Strategy

The plan to reduce energy waste in buildings

Guide to reducing energy and saving the world

Obtain leadership (and stakeholder) buy-in and commitment

Benchmark buildings

Establish KPIs and set goals

Create action plan

Implement

Evaluate progress at specified intervals

Re-assess performance and adjust action plan accordingly

Courtesy of the Strategic Energy Management Program

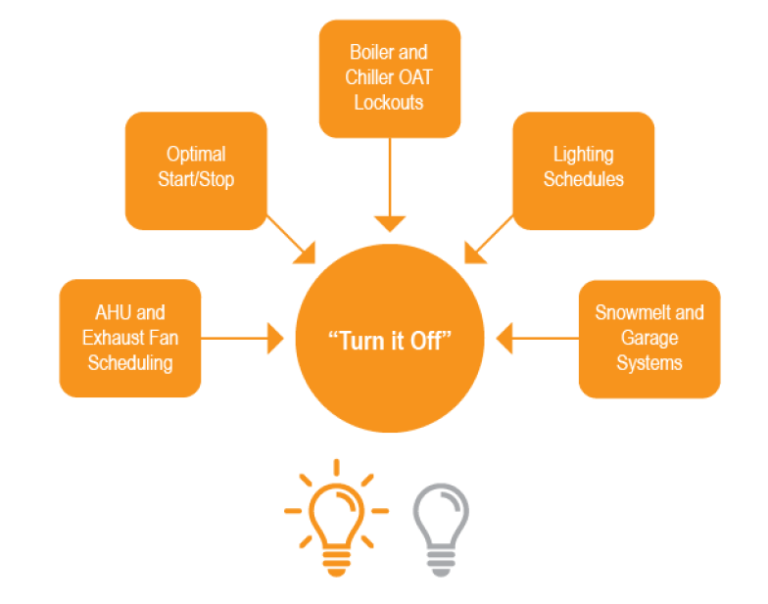

Simple approach to finding opportunities

The cheapest kWh is the one never used. Pieces of equipment have a funny way to staying on when they don’t have to be. Particular items to stay on the lookout for:

- AHU, EF, and Boiler schedules

- Optimal Start/Stop sequencing

- Boiler and Chiller lockouts

- Lighting schedules

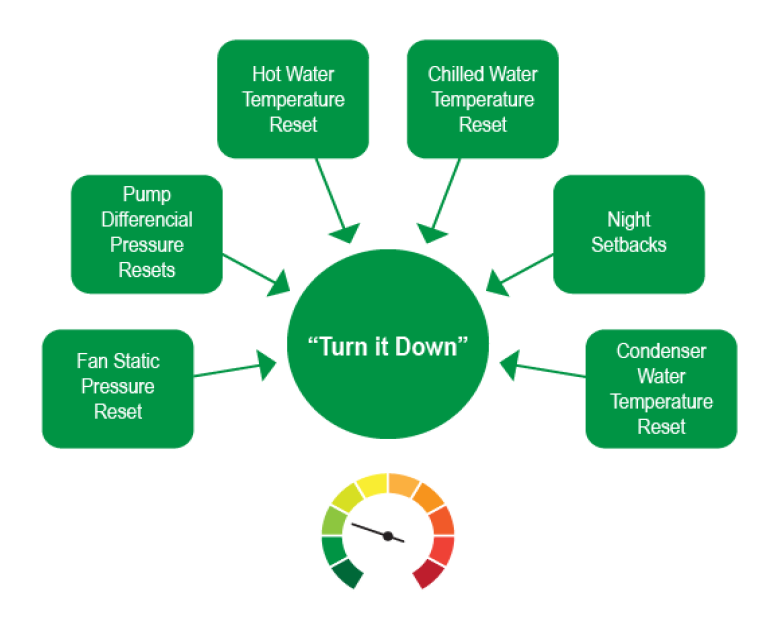

Often times we find that we are using too much of a resource than needed. In particular:

- AHU duct static pressure and temperature resets

- Pump differential pressure resets

- Heating hot water temperature resets

- Chilled water temperature resets

- Condenser water resets

- Night airflow and temperature setbacks

- Fumehoods

- Bio saftey cabnets

- unoccupied labs

- Exhaust fan stack velocity reduction based on wind speed and direction

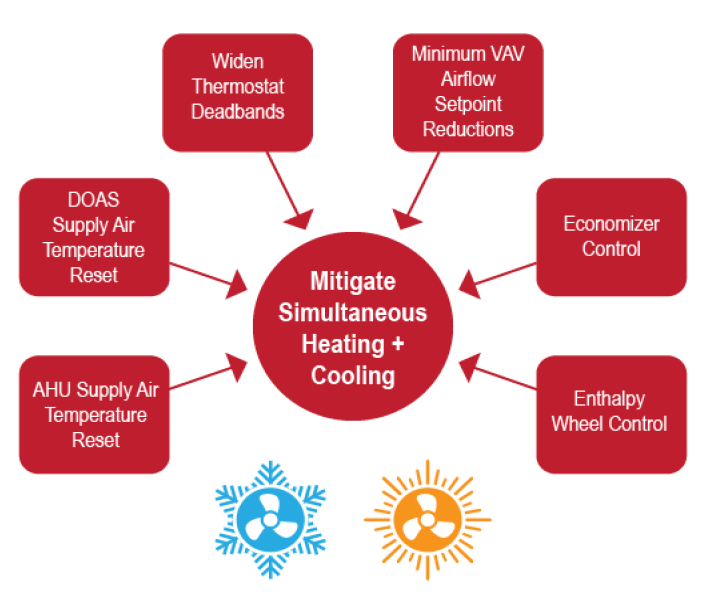

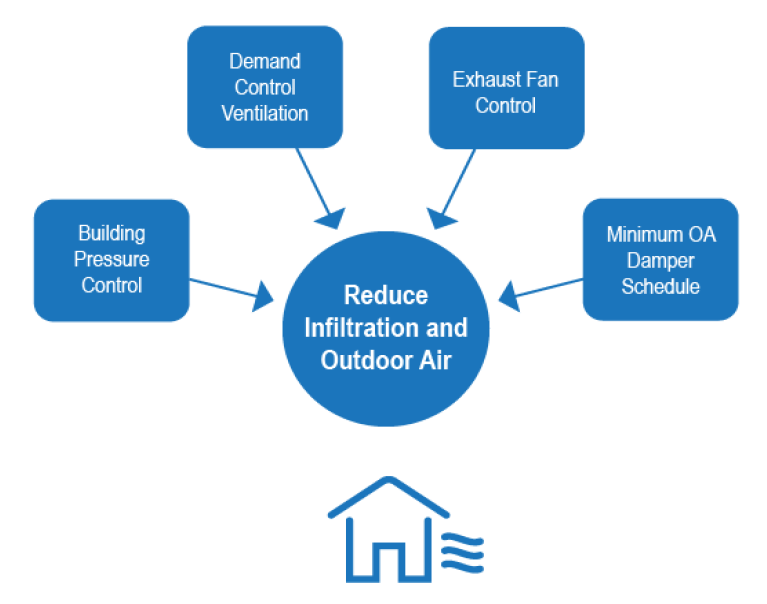

Controls are smart in today’s industry. We can leverage that with automation. Many ways we can do this are:

- Changing OAT based resets to Trim & Respond based resets where applicable

- Tune AHU, EF, hot water, and other resets

- Widen temperature deadbands

- Minimum VAV airflow setpoint reductions

- Tune economizer and minimum OA damper schedule control

- Implement demand control ventilation

- Building envelope sealing

Thing are forgotten about or ran to failure. A large opportunity, but often timely and costly is to repair it.

- Repair large equipment e.g., AHUs, EFs, Boilers, Chillers

- Zone level e.g., VAV boxes and controls

Courtesy of Pacific Northwest National Laboratory

Customized approaches to

achieve your Reduction goals

Saving the world one kwh, therm, and ccs at a time.